2715 Fiberglass insulation sleeving coated with polyvinyl Chloride resin

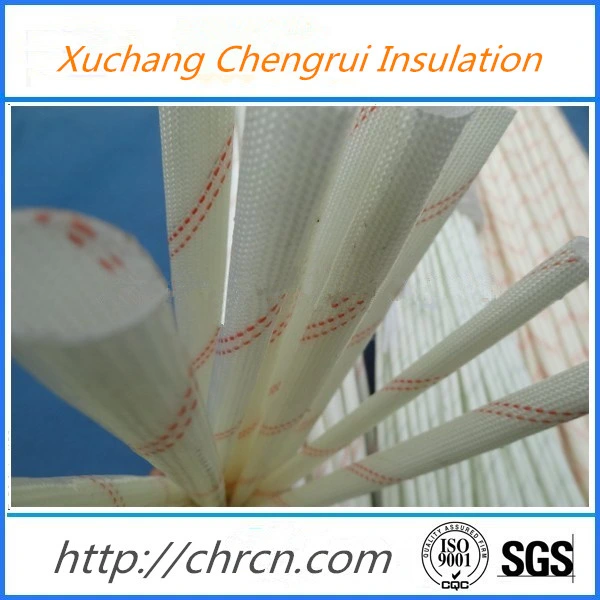

1 .Description: Electrical PVC fiberglass Insulation Sleeving is made from non-alkali fiberglass sleeving coated with polyvinyl chloride resin under the high temperature.

It is widely used as insulating and protection material for motor and electric appliance.

2.Specifications:

1).resistance temperature is 105°C

2).breakdown voltage:1.5kv 2.5kv 4.0 KV.

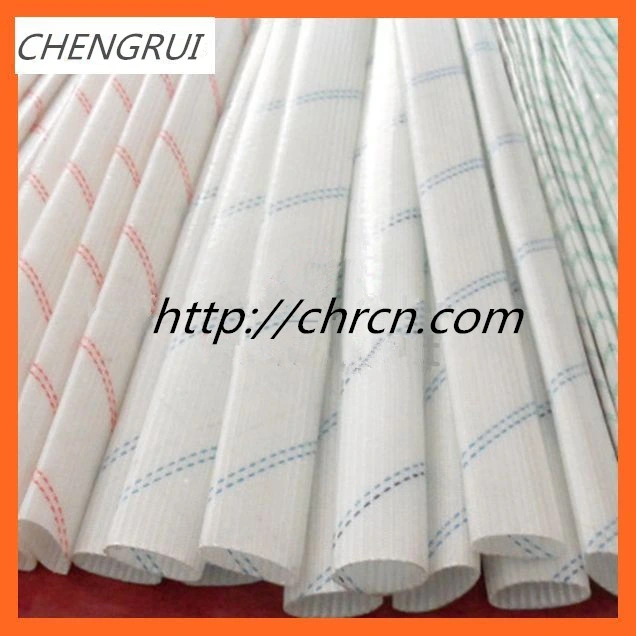

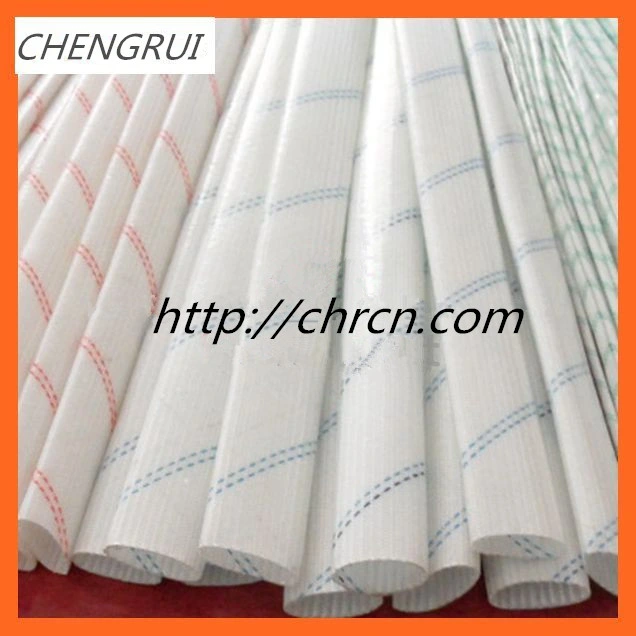

3).Diameter: 0.5-40 mm

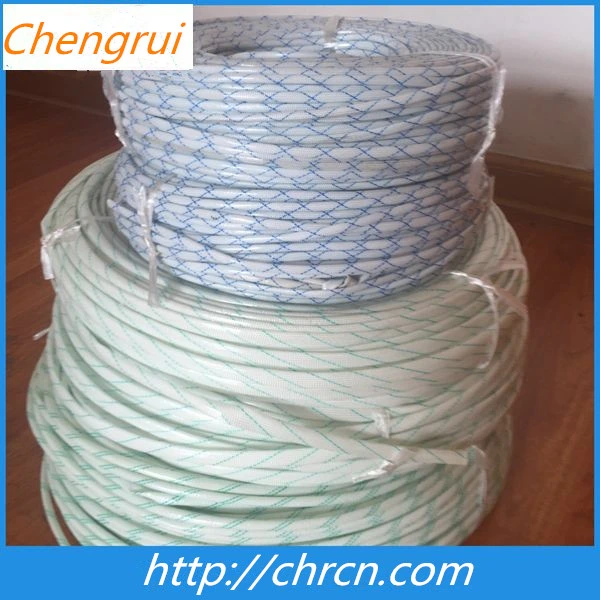

4).Packing: 1meter or 50-100m/roll with carton or bag, can be according to customer's request

5).Color: red line, blue line and all kinds of color

| Model No. | Product Name | Components | Temp. Class | Features and Applications | |

| Basic Material | Impregnated Varnish | ||||

| 2715 | Polyvinyl chloride coated fiberglass sleeving | E-glass fiber braided sleeving | Modified polyvinyl chloride resin | A(105°C) | - Excellent softness, elasticity,dielectric properties and chemical resistance - As wiring insulation and mechanic protection for motor,electric instrument and radio equipment. |

| Item | Unit | Normal value | ||||

| inner dia.& wall thickness(mm) | mm | inner dia(mm) | wall thickness(mm) | |||

| standard | tolerance | min | max | |||

| 0.5;0.8 | ±0.10 | 0.20 | 0.50 | |||

| 1.0;1.5;2.0;2.5;3.0 | ±0.15 | 0.20 | 0.75 | |||

| 3.5;4.0;5.0;6.0;7.0;8.0 | ±0.25 | 0.30 | 0.75 | |||

| 9;10;12;14;16;18;20 | ±0.50 | 0.40 | 0.90 | |||

| Bending after heating | / | No cracking or detachment of coating shall be visible after bending around mandrels after 96h at 150ºC | ||||

| Bending at low temperature | No cracking or detachment of coating shall be visible after bending around mandrels while at -25ºC | |||||

| Breakdown voltage | kv | Average | Lowest | |||

| Room temp. | 4.0 | 2.5 | ||||

| Elevated temp. | 1.2 | 0.8 | ||||

| Damp heat | 1.2 | 0.8 | ||||

| insulation resistance | MΩ | ≥1.0X103 | ||||

| The quality warranty period | 6 month | |||||

| Temperature index | 105ºC | |||||